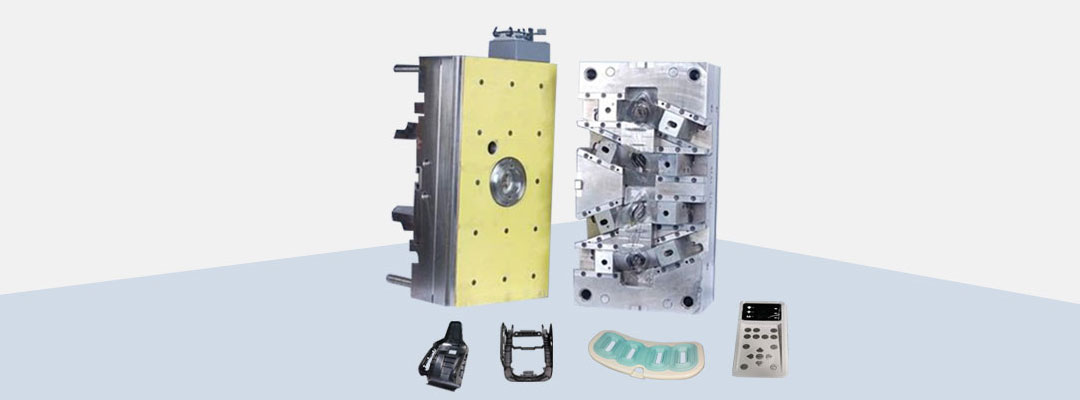

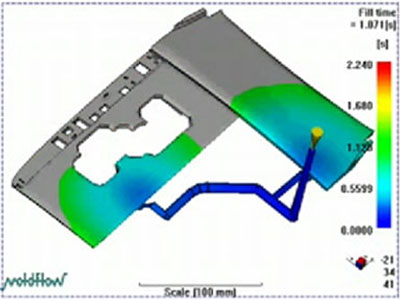

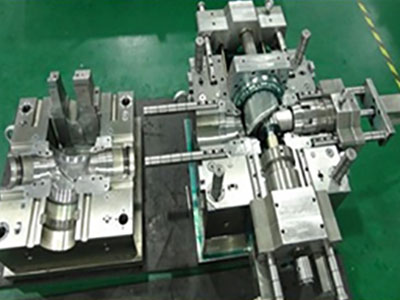

Coupled with 35 sets of domestic HAITIAN injection molding machines ranging from 90ton to 700ton, our team of seasoned designing and manufacturing professionals are large enough to carry out custom injection mold making in-house. As an expert manufacturer in the custom injection molding industry, we do not consider ourselves as an injection mold manufacturer only, but far more as a competent injection molding solution provider. Our aim is to offer the quality product to meet customers’ needs and add the absolute best value to their business.