- Home

- WHAT WE DO

- Injection Molds

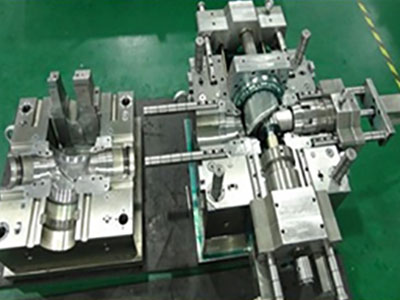

Injection Molds

Shenzhen ATOP Mould Co,. Ltd offers custom injection molds for a variety of industries to create bespoke plastic parts. Our engineers will help you to design and manufacture plastic injection molds, solving your mass production needs for large amount of custom injection molded parts.

Our injection molds are skillfully manufactured and carefully inspected to satisfy your expectations on productivity and processing quality. If well-maintained, mold has a guaranteed life span of a million shots. The materials of mold cavity and core are mainly from Japan, Sweden, and Switzerland, i.e. S136 (heat treatment), S136H, NAK80, ensuring long service life.

Whether you work in automotive electronics industry or consumer products industry, Shenzhen ATOP Mould Co,. Ltd can turn your concept into custom injection molds beyond your expectation.

Our monthly production capacity of various molds is 40 sets in total.

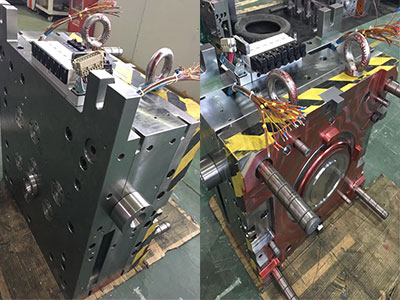

Stack Mold

High-volume production of lightweight and thin productsA stack mold can maintain mold size and machine size by adding a second layer of cavities which are parallel to the first layer. The filling, packing and cooling time of the stack mold will be extended and the injection pressure increases accordantly, resulting in an improved productivity and reduced production cost at same time. Only the mold opening and closing time will lead to a slightly increased cycle time.

Reduced part costIn contrast to a single face mold with same amount of cavities, the stack mold can help reduce 20% to 35% cost of molded products, while improving productivity of 70%.

Get in touch with us